(this is part of an ongoing DorkbotPDX workshop series being sponsored by TempusDictum, Inc.)

Posts Categorized: Dorkbot

Benito#7 The next big thing.

Note: This work is ongoing see the Benito info page for current info…

Arduino Cult Induction — Follow up part 1.

First of all I was really happy that so many people showed up and got as far into their construction as they did.

27 people and only one dead board.

I now know that getting all of that done in under 3 hours was a little ambitious. (The pacing was initially based on the photo session at http://www.flickr.com/photos/7175086@N05/sets/72157604783725339/ which took 20 minutes from start to finish)

For those of you who were unable to finish the cable Jacob Hedwig has provided a clear picture of a working cable at

Benito: My first at90USB162 project.

Note: This work is ongoing see the Benito info page for current info…

Introduction.

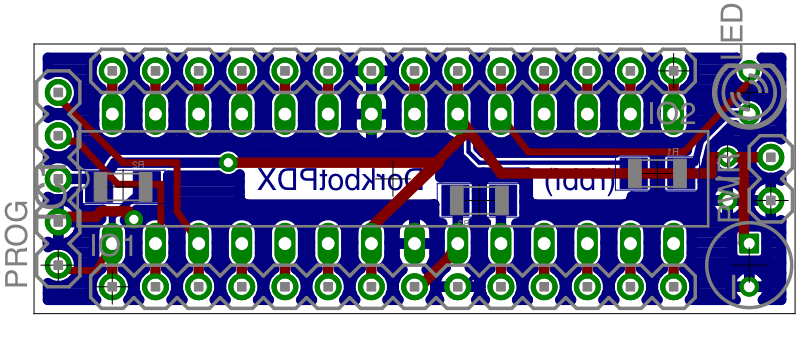

The Benito Board is an at90USB162 board intended for use in programming and communicating with microcontrollers which have serial based bootloaders.

Among those are the Phillips lpc21xx series ARM chips, the Dallas Semiconductor, DS500x family and Atmels using any number of STK500 compatible bootloaders.

Breadboard Thingy (rethinking the ft323rl board)

I sent my son to his mom’s with one of the USB Serial boards I built along with a breadboard, an RBBA a pile of resistors and an led array. I thought about this arrangement and decided that I would try to build a breadboard attached programmer that would not be dangling off the edge of the board and in the way.

A single sided ft232rl based arduino programming board.

I was so happy with the boards I did the other day that I decided to make some small boards for the ft232 so that aidan would have a programmer for his breadboard RBBA. I made 20 of these boards so if anyone wants one they can order the following parts to the group order.

| QTY | Supplier | Part number | description | cost |

|---|---|---|---|---|

| 1 | DIGIKEY | 604-00043-ND | IC FTDI FT232RL USB-SRL 28-SSOP | 4.02 |

AYou use it. |

|

Dorkbotpdx Arduino Programmer

Last week Eric (dr twist) and I got carried away and scored 100 Really Bare Bones Boards (rev A) from wulfden (http://www.wulfden.org/freeduino/freeduino.shtml) for $1.10 a board with shipping, along with the last group order which we ordered enough parts to make the 100 into “kits”. In order to program the 168s I built a programmer around Dean Camera’s “Buttload” (http://www.fourwalledcubicle.com/ButtLoad.php) butterfly based programmer and the 28 pin ziff socket that Paul Stoffregen (http://dorkbotpdx.org/wiki/PaulStoffregen) offered to loan us.

Arduino (adaboot) Programmer.

I was using the programming half of a a bulky prototype that I have been working on to program one of the mice from “Thing-a-day” Day 1 and I looked at the pile hanging precariously off of the coffee table and thought to myself.

I was using the programming half of a a bulky prototype that I have been working on to program one of the mice from “Thing-a-day” Day 1 and I looked at the pile hanging precariously off of the coffee table and thought to myself.

“I need to just build one of these. “

passive=bad active=good

http://www.circuit-fantasia.com/

http://www.circuit-fantasia.com/

I think I have a new mantra

,